The ‘All-Star’ Sliotar

It is hard to believe now but when Cummins Sports opened its doors in 1971 it was well nigh impossible to source a supply of sliotars (Hurling Balls) for our customers.

O’Neills of Capel St. in Dublin were the main manufacturers but they didn’t make them in sufficient numbers to provide us with a regular supply and, apart from that, a few individuals – mainly shoe-makers working from home in their spare time – supplied local clubs with balls.

Sliotars were like gold dust and clubs – and, indeed, county teams – resorted to all kinds of tricks to keep their meagre supply playable. A favourite trick was to whitewash old balls to give them the appearance of being new but the deception was quickly exposed once hurling began.

My late father, Willie Cummins, who had recently retired from Dunlop’s shortly after the Prince’s Street shop opened its doors and was mad keen to get involved in the business he had co-founded, was given the project, “Dad, find us sliotars – anywhere you can, just find us a supply of sliotars”

At this stage we were really desperate as we had clubs and counties clamouring for balls

At this stage we were really desperate as we had clubs and counties clamouring for balls and we felt we were losing credibility as a sports retailer in not being able to supply them.

I really don’t know what we expected my father to come up with – certainly not a ball that would win favour nationwide within a few short years! – but we were anxious to keep him occupied (and out of our hair) while we got on with the business of running a sports shop.

Despite our scepticism, Dad took to the project with gusto – he was never one to back down from a challenge – and began by dissecting old balls and stitching them back together again, “Just to get an idea how the damm things are made”

In those days the core of a sliotar comprised of a small cork ball – about the size of a golf ball – wound tightly around by knitting wool to form a firm round ball. This was then covered by two figure-of-eight shaped pieces of leather stitched together with a raised rim all round to form the shape of the finished ball. There really was a lot of work in a sliotar! (Today the core is a moulded synthetic ball, which has much better durability, holds its shape and is waterproof and, so, cuts out much of the preparity work of yore)

he couldn’t turn them out in sufficient numbers to satisfy the demand in the shop

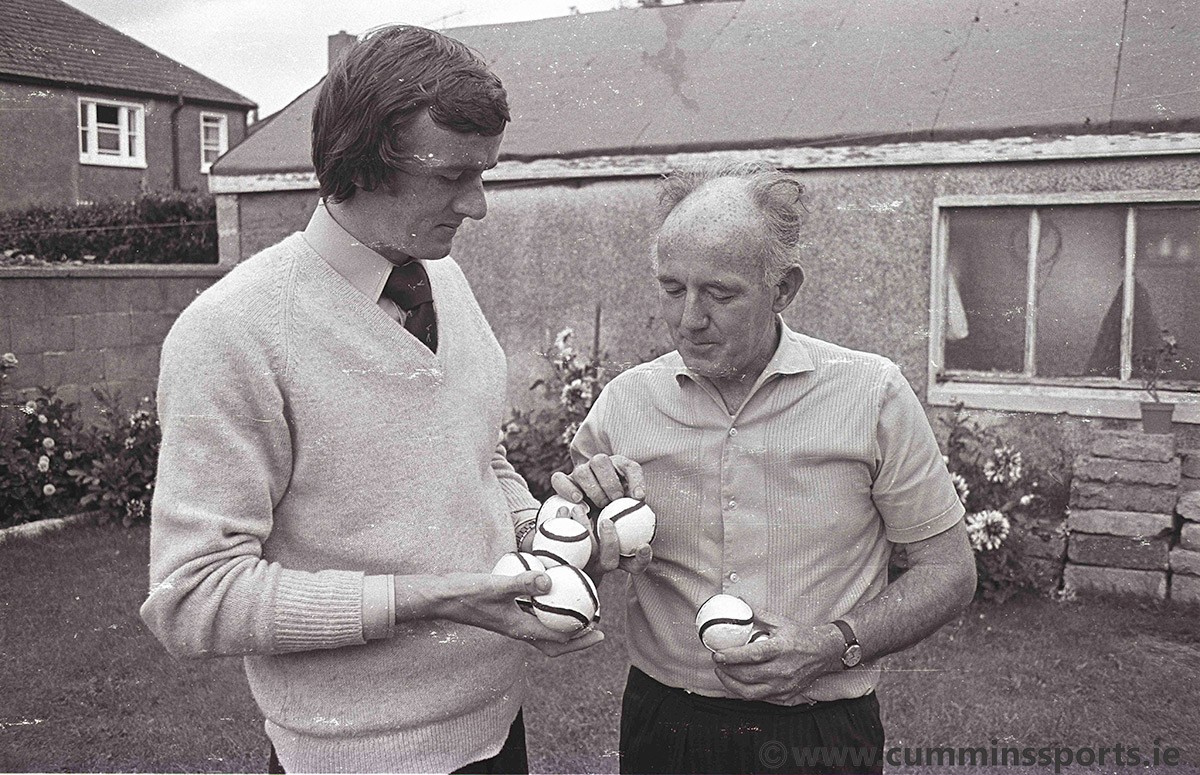

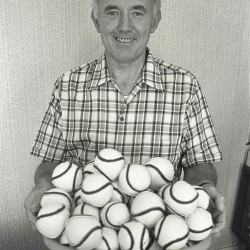

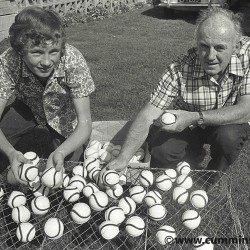

Slowly but surely Willie got the knack of making a sliotar and within a matter of weeks he was turning out balls that would stand comparison with any in the country. The problem then, of course, was that he couldn’t turn them out in sufficient numbers to satisfy the demand in the shop. So he recruited a retired next door neighbour in Ballinlough, a brother-in-law in Glounthaune, a friend in Killeagh, a retired colleague from Dunlop’s living in Blackrock, a retired shoemaker from Ballinhassig until, eventually, he had a string of ‘auld lads’ like himself, working from home and making handy ‘pint money’ for themselves without stepping outside their back doors.

The pinnacle of Willie’s career as a sliotar man was in 1976 when the “Willie Cummins All-Star” was chosen as the official ball for that year’s All-Ireland senior hurling final in Croke Park between Cork & Wexford. Having two sons, Ray & Brendan, playing on the victorious Cork side that day must have been the icing on the cake for Willie, sliotar maker supreme.

Comments are closed.